Chief Investigators: Professor Yue Liu and Professor Yan Zhuge

Year Commenced: 2019

Problem

Drinking water treatment sludge (DWTS) is a typical by-product of drinking water treatment plants. Sludge produced from treatment processes generally accounts for 1 to 3% by volume of the raw water, and concerns are growing about how to deal with this, both economically and environmentally.

The disposal costs for one large Australian utility were estimated as greater than $1.5 million per annum and exceeded $6 million per annum for one large interstate utility. This expenditure accounts for a significant part of the total cost of water treatment.

Project Summary including how the problem was solved

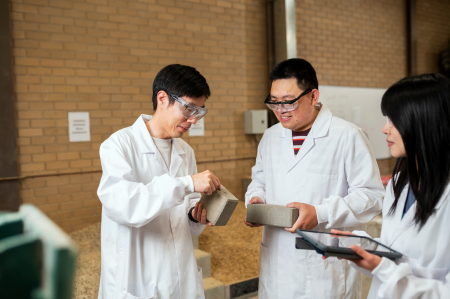

Our project team devised a way to successfully reuse DWTS as sand and cement in concrete, which is the most consumed construction material in the world. This green engineering solution for stockpiled sludge not only lowers landfill disposal costs but also conserves the land for the water industry. By valorising water industry waste, this project will also take a big step forward in the circular economy.

Impact

Considering the vast consumption of concrete, replacing sand and cement (essential components in concrete) with DWTS provides a thorough engineering solution for a significant problem. Effectively eliminating stockpiled sludge can improve water operation system efficiency, because the processes involved are major factors in the design and operation of all water treatment plants. These efficiencies and the related cost savings can significantly improve the competitive capacity of a water company.

Our team also discovered that DWTS with high alumina content may endow sludge-derived concrete products with superior properties, such as higher resistance to fire and alkali-silica reaction, harnessing the value of alumina in sludge. This gives the water industry an opportunity to valorise its waste and gain more commercial benefits.