The future of advanced manufacturing in Defence will be informed by data-driven decision making, facilitated by narrative visualisation and immersive technologies.

IVE are collaborating with BAE Systems Australia (BAE Systems) to deliver manufacturing data intelligence to the Hunter Frigate Class Program. The researchers have developed methods to visualise the complexities in shipbuilding and manufacturing, exposing hidden factors at play. This innovation reveals how delays and other issues could occur, allowing managers to alert stakeholders and minimise the impact, with potential savings of $3 million annually.

THE DEFENCE MANUFACTURING CHALLENGE

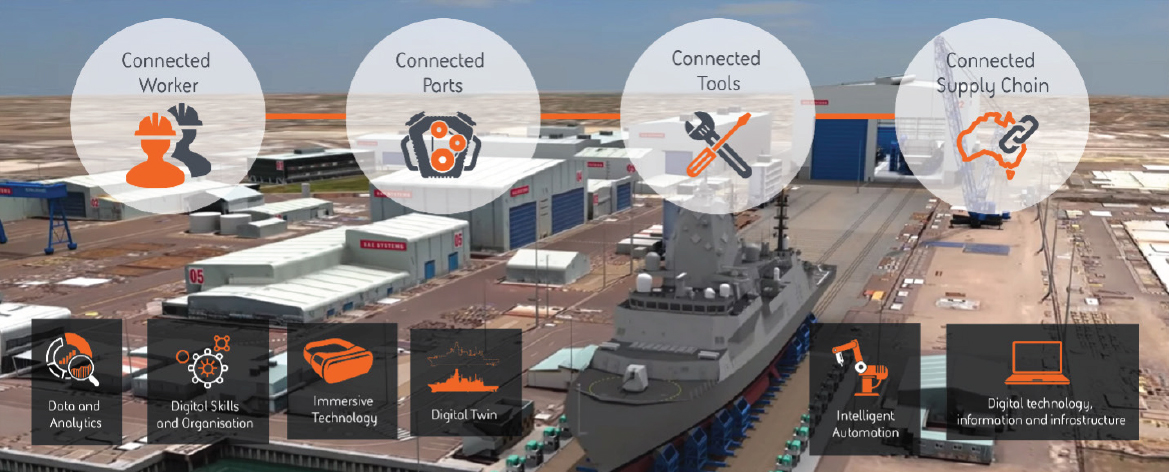

BAE Systems maritime business will design and build 9 of the worlds most advanced anti-submarine warfare frigates for the Royal Australian Navy, known as the Hunter Class. Due to the scale of the production, and the complex manufacturing environment, it is a challenge to ensure the most up-to-date and efficient ships are delivered as quickly and safely as possible. It is critical to be responsive to technological advancements and changes in the global environment. Trust must be built in the supply chain and uncertainty accounted for, with agile manufacturing needed to allow maximum flexibility. Collaboration between primes like BAE Systems, industry and academia is key to driving innovative approaches and delivering solutions that will support continuous naval shipbuilding.

VISUALISING THE STORY OF THE DATA

Using IVE’s narrative and data visualisation expertise, BAE Systems’ visualisation of the current and future state of the shipbuild, the shipyard and the supply chain. This visualisation allows stakeholders and decision-makers to see the story of the build as it evolves from start to finish. Stakeholders are provided an overview of the current state of the build as well as external factors and uncertainties in the supply chain.

The second phase of the project uses Augmented and Virtual Reality (AR/VR) to overlay the data from each zone of construction, and even from each individual workstation, to produce a 3D tabletop version of the actual build to support collaborative decision making.

IMPACT

The research outcomes are being translated into the production system, refining the manufacturing process with improved shipyard planning, construction methods and problem-solving capacity. As a result, the Hunter Program may be able to implement a more agile approach to manufacturing. Further, the research outcomes may allow for the Hunter Program to respond to world events and technological advancements as they happen, saving significant time and money, and ensuring Australia has the most advanced and efficient frigates in the world.

“The exposure that the IVE team has had to the shipyard and how that works has been invaluable to understanding the challenges that exist in industry. I believe this has enabled a more practical approach to providing solutions and the building of tangible products. Seeing their solutions starting to take shape for potential further development to yield an end product, I believe, is very rewarding. From a business perspective there is significant interest with what is being developed, as we see solutions rapidly evolving into demonstrators that solve unique problems.”

Wendy J Bourke MEng (SysSuppEng)

Senior Project Manager Innovation, Research and Technology

Hunter Class Frigate Program

![]()

For more information or to discuss potential projects contact: Andrew.Cunningham@unisa.edu.au