Local partnership delivers world-leading ‘smarts’ to shipbuilding

By Michèle Nardelli

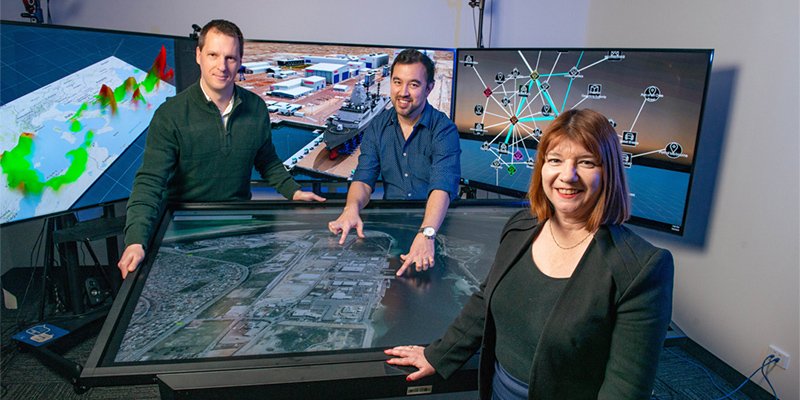

TECHNOLOGY AND ENGINEERING UniSA lecturers Dr Wolfgang Mayer and Dr Andrew Cunningham with Dr Anastasia Kuusk from BAE Systems ... UniSA research will support innovations including touchscreen conference tables to present data in a meeting room or boardroom format.

TECHNOLOGY AND ENGINEERING UniSA lecturers Dr Wolfgang Mayer and Dr Andrew Cunningham with Dr Anastasia Kuusk from BAE Systems ... UniSA research will support innovations including touchscreen conference tables to present data in a meeting room or boardroom format.UniSA is spearheading research to deliver world-leading manufacturing technologies to the Hunter Class Frigate Program.

A partnership between UniSA, Australia’s Innovative Manufacturing Cooperative Research Centre (IMCRC) and BAE Australia’s shipbuilding business ASC Shipbuilding, will see a co-investment worth more than $4 million in data visualisation research.

The research, which will be led by UniSA, will drive the development of digital manufacturing (Industry 4.0), improve shipyard planning and add unique data analytics and problem solving capacity to the Hunter program, which will deliver nine world-leading anti-submarine frigates to the Royal Australian Navy.

The Hunter class frigates will be the world’s first bow-to-stern digitally designed anti-submarine warfare frigate, and each ship involves highly complex supply chains.

The research outcomes and findings from the project will prepare Australian industry for a future that is driven by digital innovation.

UniSA chief collaborator, Professor Bruce Thomas, from the Australian Research Centre for Interactive and Virtual Environments, says the research will focus on how narrative visualisation and big data processing can deliver, reshape and refine the highly complex manufacturing environment across the timeframe required for each frigate build.

Innovations designed to consolidate information from across the shipyard will include touchscreen conference tables to present the data in a meeting room or boardroom format, specifically to support boardroom decision making; a powerful visualisation platform, purpose-designed to support detailed technical authority decision making; and a ‘big data dashboard’ that can provide real-time information to the workforce to support workforce-wide decisions.

“Fundamentally, the research project will be changing the way processes are carried out internally and externally to the shipyard,” Prof Thomas says.

“Through data fusion, machine learning and artificial intelligence data analytics, and visualisation technologies, we will be bringing intelligent planning systems and smart ‘human in the loop’ decision making to the project.

“What we learn by adapting, trialling and testing to suit the Hunter class frigate’s design – will support the prototyping later this year, but will also build significant knowledge for wider application in Australian manufacturing.

“The work will underpin a change in the way shipyards are planned and managed by enabling integrated data insights across the supply chain.”

IMCRC chief executive officer David Chuter says the partnership will ensure the Hunter class frigates are built using some of the most sophisticated innovations in manufacturing, while developing extraordinary capabilities and ongoing capacity for Australian shipbuilding and manufacturing.

“This partnership will provide enduring and uniquely Australian sovereign industrial capability and advance and mobilise local manufacturers, particularly small and medium enterprises (SMEs), to support Australia’s naval shipbuilding strategy for generations to come,” Chuter says.

Federal Minister for Industry Science and Technology Karen Andrews say the project represents innovation at its most powerful – embracing technology and a new way of doing things to improve production.

“Not only will harnessing data visualisation research help the Hunter program itself, it will also assist critical local supply chains and future projects across the manufacturing landscape,” Andrews says.

“This type of industry-led innovation that can be applied in a range of different settings will be key to charting our COVID-19 economic recovery.”

ASC Shipbuilding Continuous Naval Shipbuilding strategy director Sharon Wilson welcomes the opportunity to partner with UniSA and draw on the expertise of local researchers to drive innovation in digital manufacturing and find innovative solutions to production challenges.

“Digital shipbuilding is all about connectivity – not just within the physical and digital shipyard but with our supply chain and customer – and the research will support everyone and every single part and product on the Hunter program to be connected,” Wilson says.

“Together we’re creating a first-of-its-kind digital environment through the entire ship design and construction to improve productivity, quality and safety outcomes in the shipyard, and underpin growth and longevity in the naval shipbuilding industry in Australia.

“These innovations will be significant across the local supply chain so that Australian manufacturers can start their digital journey, building their capability to be involved in the Hunter program and future shipbuilding projects.”

Other Stories

- 35-second body scan could tell you the sport you’re best suited to

- Insects inspire infection resistant dental implants

- Is it a bird, a plane? Not superman, but a flapping wing drone

- Could our beloved Aussie rules footy be turning into soccer?

- From the Vice Chancellor

- Achievements and Announcements

- Health students step up to the plate to help curb Australia’s $170b medical bill

- Remote internships providing students with rewarding experiences

- Video: How to keep your brain healthy

- Which is more creative, the arts or the sciences?

- Local partnership delivers world-leading ‘smarts’ to shipbuilding

- MBA student creates Australia’s most eco-friendly magazine wrap

- Pandemic prompts students to solve challenges creatively

- The latest books from UniSA researchers

- In Pictures: Open August and VC Excellence Awards online event