Reviewing and analysing structural properties of Machine Graded Pine

Lead researcher: Associate Professor Rameez Rameezdeen

The Project

The Australian softwood producers work hard every day to maintain the highest standards of swan timber product in the market. There are constant changes in forest resource, grading technology and market demands. Given the ongoing changes it is important to establish the physical and mechanical properties of a nationally pooled Australian structural softwood timber sample which can be referenced against design properties published in AS1720.1-2010: Timber Structures - Design

Methods. Data captured through this project will allow the Australian timber industry to continue to maximize on the opportunities available in ever changing forestry, milling and construction sectors.

Our Research Approach

- 13 mills from all parts of Australia participated in the project.

- An enthusiastic team of researchers and technicians were involved in the project.

- A dedicated in-grade timber testing facility at UniSA Mawson Lakes campus was used for testing.

- Secure data storage and analysis is through a system database developed by UniSA using ‘REDCap’.

- Sampling started in January 2020.

- Currently more that 95% of testing completed and the project is due to finish by end of this year.

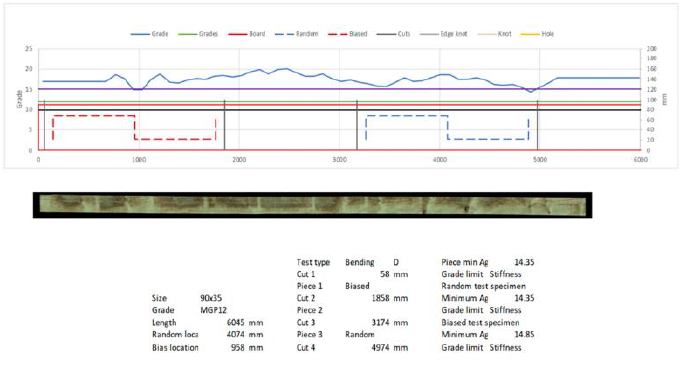

- The grading information provided by the mills was used as part of the quality control of the overall project.

- Grade profile information helped establish the expected bounds for the test results and this information was used to validate test data and identify anomalies for further investigation.

- Analysis of test data is concurrent with testing, so that results will be available soon after the last test is complete

- Data validation checks are concurrent with sample markup and testing to ensure the validity of the population tested

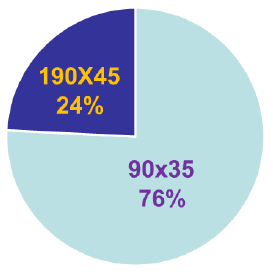

Sample Composition

Sample Composition

Photographs or grading images were used to confirm the identity of each board marked for cutting

Our Findings

The project has:

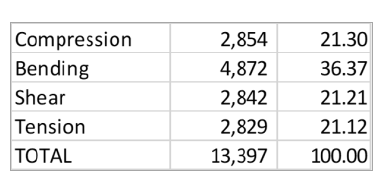

- Undertaken 17,800 tests

- Provided feedback to the industry on all of the structural properties of their products

- Verified compliance with the relevant Australian Standards

- Provided a benchmark of MGP properties that can be compared against the results of previous test programs

- Delivered information into a national pool of data for evaluation of the properties of the structural softwood national resource

Preliminary Results

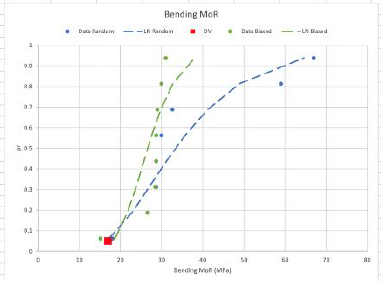

- Results to date fit the expected log-normal distribution for all strength properties well. The analysis method for the

project will comply with AS/NZS 4063.2. - An initial picture of the performance of the national population has started to emerge. However, conclusions cannot

be drawn until testing is completed.

Completed Tests

Our Team

Researchers: Rameez Rameezdeen, Julie Mills, Yan Zhuge, Xing Ma, Mark Ellis, Chris Chow, Jim O'Hehir, Ben Evans, Geoffrey Boughton (TimberED Services), Jon Shanks (TimberED Services)

Collaborative Partners: AKD Softwoods Pty Ltd, Allied Timber Products (QLD), Highland Pine Products Pty Limited, Hyne Timber Pty Limited, OneFortyOne Wood Products Pty Ltd, Timberlink Australia Pty Limited, Wespine Industries Pty Ltd, Dongwha Australia Pty Ltd, Australian Softwood Pty Ltd

Contact information

Dr Jim O’Hehir

General Manager: Forest Research Mount Gambier

Ph: +61 8 830 28997

E: Jim.O'Hehir@unisa.edu.au

Michele Cranage

Administrative Officer

Ph: +61 8 830 28902

E: Michele.Cranage@unisa.edu.au