UniSA collab delivers cladding solution that provides longevity

The upfront cost of machinery used by heavy industry is exacerbated by the continual need for maintenance. Shutdowns for equipment repair can cost more than $100K for every hour of downtime.

Experts at UniSA’s Future Industries Institute have partnered with surface engineering company LaserBond Ltd to develop some of the world’s most resilient claddings.

“We’ve refined the laser cladding technology, allowing LaserBond to create tailor-made coatings that are deposited faster and resist degradation.”

Professor Colin Hall, Researcher, UniSA

Key researcher, UniSA’s Industry Professor Colin Hall, says this research will allow for improved protection and longevity of machinery – reducing maintenance costs and downtime.

“Through this partnership we’ve refined the laser cladding technology, allowing LaserBond to create tailor-made coatings that are deposited faster and resist degradation.”

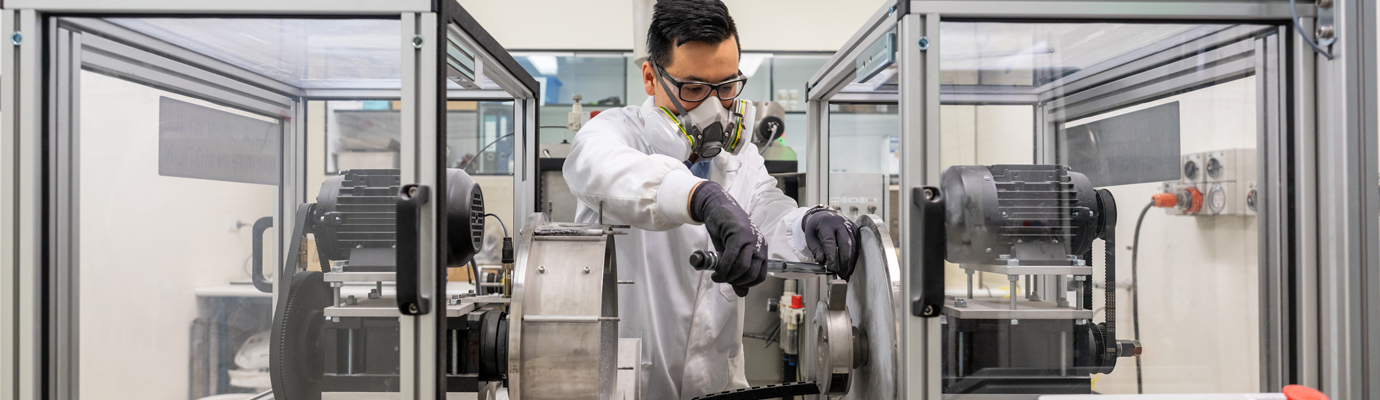

“We’ve used UniSA’s extensive tribology laboratories to perform accelerated testing in erosion, corrosion and impact abrasion,” says Professor Hall.

“We’ve combined these results to predict wear rates in the real world, which has allowed us to then inform material and process optimisation for LaserBond.

LaserBond Engineering Manager for R&D, Dr Thomas Schläfer, says the collaboration with UniSA has brought huge benefit to the business and the industry as a whole.

“This partnership with UniSA has improved our product quality and product range, while helping to reduce maintenance costs for our customers,” Dr Schläfer says.

“We've had access to UniSA expertise and facilities that we don't have in-house, which has enabled us to learn a lot about our processes and has also allowed us to showcase our improved technology to new customers.”