Author: University of South Australia’s Enterprise Hub Business Development Manager, Atif Majeed

Industry 5.0 represents a transformative leap toward sustainable, efficient, and personalised production processes. However, as is typical with any innovation, a sense of mystery and apprehension surrounds its impact on business and the workforce. This fear stems from the natural human response to change and the unknown, not from the potential of Industry 5.0 itself.

Industry 1.0 to Industry 4.0, and beyond

To better grasp what Industry 5.0 means for our economy, environment, and society, let us first briefly revise our industrial history. The 18th Century brought us the First Industrial Revolution with steam power and the mechanisation of production, which was followed by electricity and mass production in the 19th Century. Then, the 1970s gave rise to automation through computing, programming, and robotics. Finally, the Fourth Industrial Revolution built upon this automation with digital technologies with the introduction of the Internet of Things (IoT), Artificial Intelligence (AI), Big Data, Cloud Computing, and Additive Manufacturing.

The technologies, processes, and approaches used by most of our global industries are characteristic of Industry 4.0: our healthcare industry leverages IoT devices for remote patient monitoring and telehealth services; our automotive industry uses additive manufacturing for rapid prototyping; and our agriculture industry has employed autonomous tractors and drones for tasks like planting, spraying, and monitoring crops. The hallmark of this industrial era is its cocktail of productivity, efficiency, personability, and data-driven optimisation. The dawn of Industry 5.0 will build upon these advancements while forging a new era of human-centeredness and sustainability.

The difference between Industry 4.0 and Industry 5.0

Where a desire for enhanced productivity and subsequent profitability has been the driver behind Industry 4.0, and its precursors, Industry 5.0 heralds a divergence from this precedence. Industry 5.0 will demand that businesses prioritise people and the planet. The European Commission provides a fantastic definition to further illustrate this point:

“[Industry 5.0] places the wellbeing of the worker at the centre of the production process and uses new technologies to provide prosperity beyond jobs and growth while respecting the production limits of the planet.”

This eloquent explainer highlights that new technologies will be a cornerstone of this next industrial revolution, but, equally, so too will the wellbeing of our society and our environment. Where Industry 4.0 is focused on the integration of digital technologies with automation, and data exchange to enhance manufacturing efficiency, Industry 5.0 ensures a framework for industry that combines competitiveness with sustainability.

It is a shift from purely automated processes to a more inclusive and interconnected ecosystem. The dawn of this next industrial revolution will foster closer collaboration between humans and intelligent machines while ensuring outputs are ethical and sustainable.

What businesses are failing to grasp about Industry 5.0

Common queries about Industry 5.0 revolve around switching costs, threats to profit margins, strain on productivity, and market expansion barriers. Ironically, these assessments will soon become more reflective of Industry 4.0. This is because data is becoming more complex, more valuable, more insightful, and more accessible. The ever-evolving capabilities of data allow organisations (and their competitors and consumers) to trace and track global impact.

Society can now observe (and will continue to observe with starker clarity) an organisation’s energy consumption, primary resources use, byproducts, worker wellbeing, and profit margins. The intricate web of interconnected systems developed during Industry 4.0 enables this intimate view of entire supply chains. This means that businesses will no longer be able to merely attempt corporate responsibility. Consider this warning from the European Union’s Policy Brief titled Industry 5.0: A Transformative Vision for Europe:

“The Industry 4.0 paradigm… is not fit for purpose in a context of climate crisis and planetary emergency, nor does it address deep social tensions.”

The policy brief also points out that Industry 4.0 actually allows for the optimisation of business models, industrial practices, and economic philosophy that are the “root causes” of the threats we now face. So, how do we slam the breaks on an industrially-driven doomsday? Industry 5.0, of course.

How UniSA is helping industries transition to Industry 5.0

At the University of South Australia (UniSA), we work with more than 2,500 industry partners across a diverse global industry, including advanced manufacturing, defense, education, health, and digital technology. UniSA houses more than 30 research institutes, that constantly work collaboratively to solve global challenges. This cross-pollination of expertise enables our partners to enhance their capabilities.

A prime example is the work we are conducting within the Industry 5.0 realm. Currently, five UniSA research entities have combined their expertise in economics, supply chains, additive manufacturing, biotechnology, machine learning, sustainability, and resource management. This group is collaborating with a private company on a project designed to reduce road deaths to zero in a foreign country by 2030. They are using Virtual Reality and biosensors to track pedestrian behaviour, AI to predict accidents, and Cloud Computing Data to inform optimised and interconnected road infrastructure. The team is also working on design changes that can minimise the impact of vehicle collision and hence minimise loss of life and injuries.

Essentially, UniSA’s experts are helping this company improve the quality of human life, in a way that is sustainable and smart. More examples of UniSA's work in this space includes its collaborations with technology and automotive companies to develop energy-efficient trains, shatterproof car mirrors, drones that detect disease, and self-driving cars that talk to one another. Our research and expertise can be leveraged by your business, and UniSA is here to support your journey toward Industry 5.0.

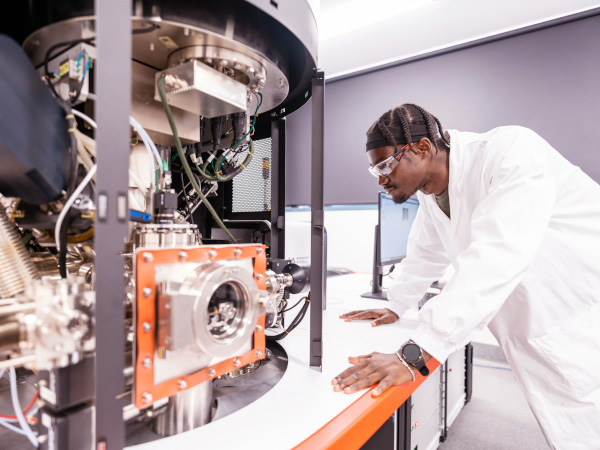

A team of UniSA researchers are working with an overseas company to reduce road accidents and fatalities.

I want to begin my transition to Industry 5.0. What should I do next?

Firstly, your organisation will need to build on its Industry 4.0 capabilities by implementing a new set of principles that meet future challenges and opportunities. Industry 5.0 requires a human-centric and sustainable approach, so priority should be given to:

Assessing your current state: Evaluate your current manufacturing processes, technology infrastructure, and workforce capabilities and identify areas where Industry 5.0 principles can be applied to improve efficiency, agility, and sustainability

Cementing leadership commitment: Senior leadership and board members will be the drivers of your transition to Industry 5.0, so develop a clear business case outlining your vision, enablers, threats, financials, and timeline of adoption

Investing in your workforce: Identify areas for upskilling and training in emerging technologies, digital literacy, and sustainable practices. Additionally, identify your future workforce pipeline (hint: UniSA students and graduates)

Investing in digital infrastructure and connectivity: Decide what capabilities you want to enhance. Consider investment in IoT, collaborative robotics, artificial intelligence (AI), blockchain, digital twinning, and big data analytics to enable real-time data collection, analysis, and decision-making. You can also access UniSA technology and facilities.

Collaborating with the experts: Connecting with vendors, research institutions, and, of course, universities, will enable strategic and informed adoption of new plans, technology, skills, and processes.

Partner with UniSA for Industry 5.0

Data, innovation, worker wellbeing, and sustainability are not adversaries but allies in the journey toward progress. Embracing Industry 5.0 allows us to explore how profits and overall health of people and plant can advance hand in hand, fostering an era where economic success and societal benefits harmoniously coexist.

UniSA’s research expertise can be leveraged by your business. You can begin your journey by connecting with UniSA’s Enterprise Hub for guidance and support. You can visit our website to learn more, make an email enquiry or phone us on 08 8302 3482.

About Atif Majeed

Atif Majeed is a Business Development Manager at UniSA’s Enterprise Hub. With an academic background in electrical engineering and entrepreneurship, Atif's career has been underpinned by a passion for future technology. As a Fulbright Scholar, he brings a global perspective to UniSA, connecting industry leaders with research experts to trigger innovation and advancements across the advanced manufacturing, AI, computing, environment, and mining industries. Connect with Atif via UniSA's Enterprise Hub.

Contact the Enterprise Hub

Get in touch with us to find out how we can support your business needs.

Make an enquiry online or call us to discuss your idea