The problem

The upfront cost of machinery used by heavy industry is exacerbated by the continual need for maintenance. Shutdowns for equipment repair can cost more than $100K for every hour of downtime. Therefore, a competitive advantage is to increase the longevity of machinery and to improve the repair, remanufacture and re-use of componentry.

The solution

Experts at UniSA’s Future Industries Institute have partnered with surface engineering company LaserBond Ltd to developed some of the world’s most resilient claddings.

Key researcher, UniSA’s Industry Professor Colin Hall, says this research partnerships has refined LaserBond’s laser cladding technology – which will allow for improved protection and longevity of machinery.

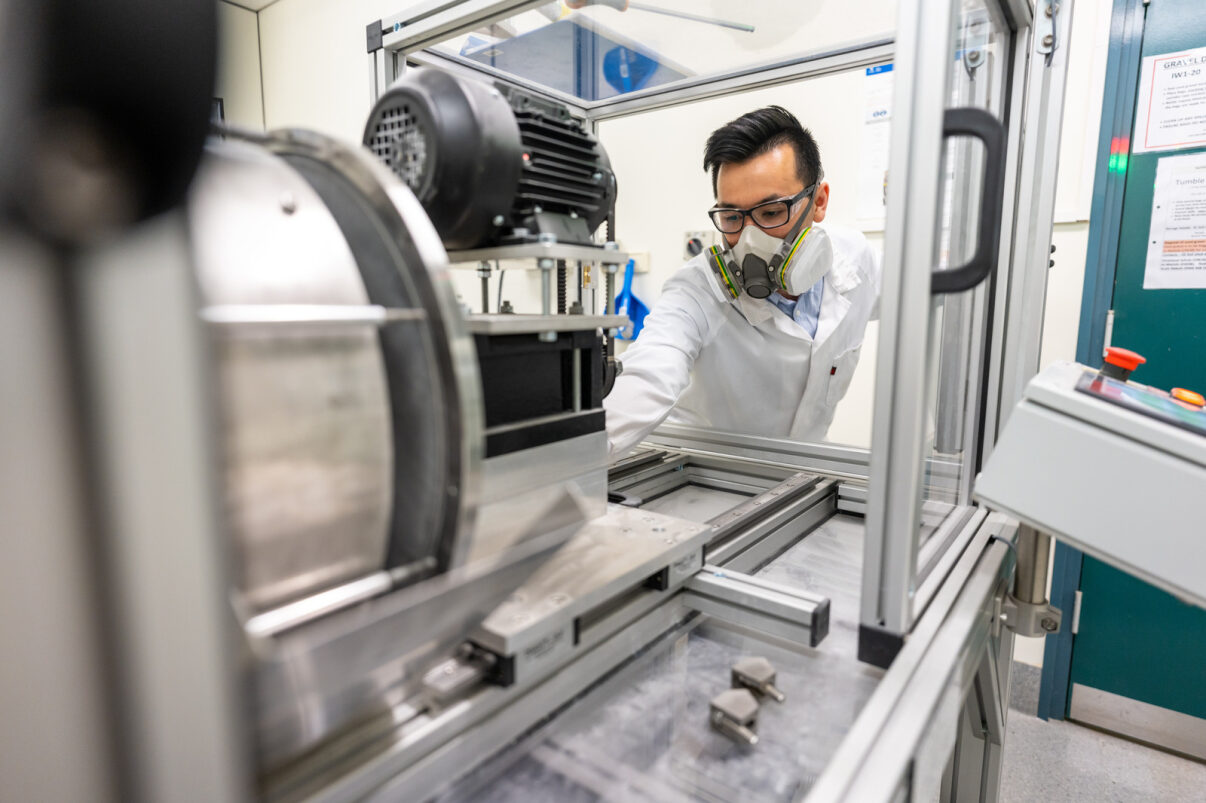

“We’ve used UniSA’s extensive tribology laboratories to perform accelerated testing in erosion, corrosion and impact abrasion,” says Professor Hall.

“We’ve combined these results to predict wear rates in the real world, which has allowed us to then inform material and process optimisation for LaserBond.

“Through this partnership we’ve refined the laser cladding technology, allowing LaserBond to create tailor-made coatings that are deposited faster and resist degradation.

“Not only have we been able to increase the lifespan of minerals processing equipment, but we have also been able to bring our university students in on this project, and thereby educate them to become future surface engineers.”

LaserBond is committed to reducing the environmental impact of the heavy industry by ensuring parts can be used for as long as possible, and as many times as possible.

The company’s technology can also be used to replace hard chrome plating – a process that carries significant health and environmental concerns.

LaserBond Engineering Manager for R&D, Dr Thomas Schläfer, says the latest breakthrough in Research & Development with UniSA has brought huge benefit to the business.

“This partnership with UniSA has improved our product quality and product range, while helping to reduce maintenance costs and increasing our revenue,” Dr Schläfer says.

“We've had access to UniSA expertise and facilities that we don't have in-house, which has enabled us to learn a lot about our processes and has also allowed us to showcase our improved technology to new customers.

“The university has been able to expand its capabilities for us to generate industry-relevant outputs and engagements, which helps the sector.

“For example, one outcome of our work together is a component for the drilling industry where the team developed a surface engineering solution that increased the lifetime by a factor of 10.”

This work has been supported by the ARC Industrial Transformation Training Centre – in Surface Engineering for Advanced Materials (SEAM) and the Australian Government through its Innovations Connections scheme.

UniSA is dedicated to supporting the growth of businesses and industries through research collaborations. Connect with UniSA’s Enterprise Hub to discover how your business can benefit from UniSA’s experts, research, facilities, and technology. Enquire now.

Partners involved

Related services

Contact the Enterprise Hub

Get in touch with us to find out how we can support your business needs.

Make an enquiry online or call us to discuss your idea