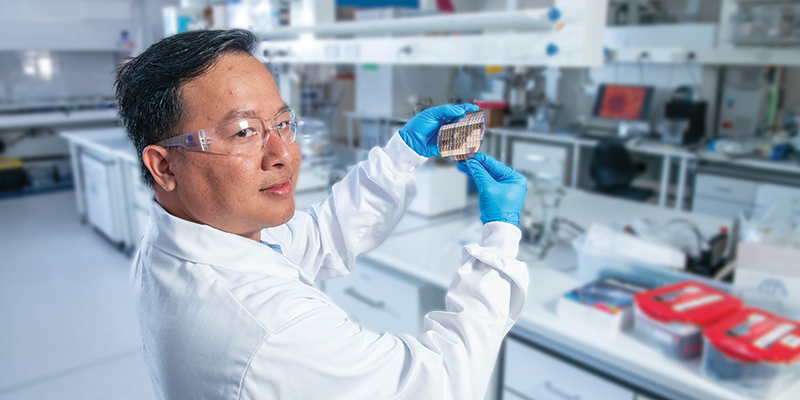

Professor Benjamin Thierry is using nanotechnology to improve cancer treatment. Photo by Brenton Edwards.

Professor Benjamin Thierry is using nanotechnology to improve cancer treatment. Photo by Brenton Edwards.

A nanometre (nm) is 0.000000001 metres, and by convention, the term nanoscale covers dimensions between 1nm and 100nm. At that scale, due to a combination of quantum effects and the extensive surface area present with nanomaterials (see side bar for a full explanation), the physical properties of a substance can be quite different to those exhibited by larger forms of the same material.

By manipulating the exact size, shape and structure of nanomaterials, it is possible to ‘tune’ many of the properties they display. For example, quantum dots are tiny semiconductor particles a few nanometres in size, increasingly common in television displays. Under UV illumination, these dots emit visible light, and depending on their exact size and structure, will glow a different colour, from violet to yellow to dark red.

Harnessing the properties of various substances at this scale has become the brightest hope for a burgeoning range of technologies, from dull but practical applications like more colourful carpets and odourless socks, to dazzling innovations such as increased energy transmission and quantum computing.

Among the many promising applications of nanomaterial research, nanomedicine has emerged as one of the most exciting fields in the health sciences. Professor Benjamin Thierry is a research leader at UniSA’s Future Industries Institute (FII) and head of the South Australia node of the ARC Centre of Excellence in Convergent Bio-Nano Science and Technology, and he says the nanoscale opens up a world of possibilities for health and biomedical researchers.

“One of the key basic concepts of medical nanotechnology is that when you reduce the size and reach of that nanoscale, you introduce a whole range of new properties that can be precisely tuned to open new biomedical applications,” Prof Thierry says. “So, for instance, researchers at UniSA are using silver nanoparticles that can fight infection, and my team is using nanoscale semiconductors that allow us to detect the presence of protein biomarkers in the blood at very, very small concentrations.”

As many biological processes occur at the nanoscale, understanding how to manipulate and tailor material at that level offers distinct benefits to biomedical researchers. Not only are they able to take advantage of the unique properties of nanomaterials, they can also base innovation on the most fundamental techniques of nature, essentially borrowing methods evolved over 3.5 billion years to solve some of today’s most pressing challenges.

Here, we look at six of the most promising ways in which UniSA researchers are using the very small to make a big contribution to a healthier future.

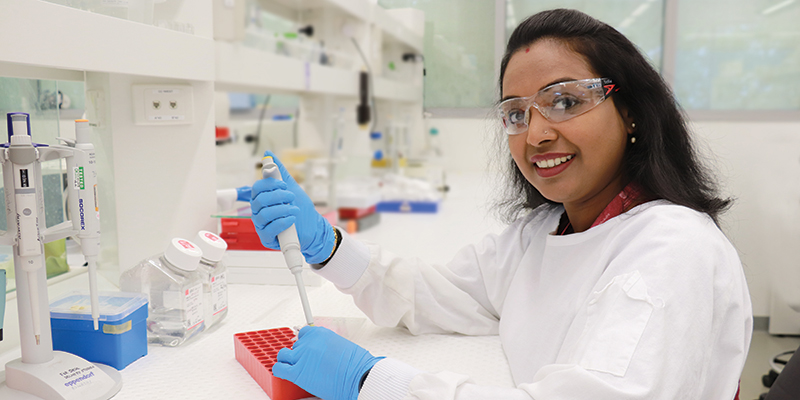

Dr Duy Tran is developing a cheap, easy and accurate test for preeclampsia. Photo by Brenton Edwards.

Dr Duy Tran is developing a cheap, easy and accurate test for preeclampsia. Photo by Brenton Edwards.

SIMPLIFYING PREGNANCY COMPLICATION CARE

Prof Thierry and his team are currently engaged in two world-leading research areas, both of which highlight the immense potential nanotechnology promises for improving human health – more accurate prediction of pregnancy complications and improved precision in cancer treatment.

“We’re focused on the diagnostic side of things, involving a lot of nano-technology,” Prof Thierry says. “We mostly focus on either using nanoparticles to assist in imaging diseases like cancer, or we are using nanomaterials to better detect biomarkers for disease.”

Prof Thierry is working closely with UniSA researchers including Dr Marnie Winter and Dr Duy Tran to develop diagnostic techniques to improve identification of pregnancy complications such as preeclampsia and preterm birth.

Dr Tran says preeclampsia affects 5 per cent of all pregnancies and directly causes the death of about 500,000 infants and 76,000 pregnant women worldwide each year.

“Globally, the disparity in adverse birth outcomes between low and high-income settings is well established,” Dr Tran says. “Most preterm births occur in South Asia and sub-Saharan Africa, and significant disparities in adverse birth outcomes also exist between remote and urban Australia, including for Aboriginal Australians.”

The key cause of this disparity is a lack of a quick, cost-effective and reliable point-of-care diagnosis. Early detection and intervention are crucial in managing complications, but existing tests require centralised laboratories and expensive state-of-the-art technology, both of which are largely absent in remote areas.

“We are building a diagnostic device that could be operated with minimal training by nurses and other primary healthcare providers within regional and remote communities,” Dr Tran says.

“Our team has developed a solid-state biosensing platform that measures blood biomarkers linked to placental dysfunction, with a turnaround time of just 40 minutes from a single drop of finger-prick blood,” Dr Tran says.

This platform, based on nanostructured metal oxide field effect transistors, relies solely on standard microfabrication facilities, enabling large-scale, low-cost production of the sensing units.

“To date, five pregnancies with confirmed preeclampsia have been successfully tested and validated against a centralised standard assay,” Dr Tran says. “We are currently developing our device further in the format of a portable analyser unit and single-use disposable cartridges and, with the support of UniSA Ventures (the University’s commercialisation company), we are engaging with the Medical Device Partnering Program to eventually commercialise the platform.”

The Ferronova cancer imaging system, co-developed by Dr Aidan Cousins, is being trialled at Royal Adelaide Hospital. Photo by Brenton Edwards.

The Ferronova cancer imaging system, co-developed by Dr Aidan Cousins, is being trialled at Royal Adelaide Hospital. Photo by Brenton Edwards.

A MORE PRECISE APPROACH TO CANCER

Successful cancer treatment relies on accurate diagnoses and detection of how far the disease has spread from a primary tumour. The lymphatic system is the primary pathway for the spread of most cancers, particularly those in the head and neck.

Prof Thierry says about 20 to 25 per cent these cancers spread through the lymphatic system, requiring “very aggressive treatment”.

“Currently, it is very difficult to tell if the cancer has spread, so most doctors treat all patients in this aggressive way as a precaution,” he says. “The patients pay the price with increased morbidity, when maybe as many as 80 per cent don’t need this aggressive treatment.”

In conjunction with UniSA spin-out company, Ferronova, Prof Thierry and Future Industries Institute (FII) research associate, Dr Aidan Cousins, have developed a biodiagnostic system to refine cancer detection. The system consists of a magnetic probe and injectable magnetic nanoscale tracers, able to detect the spread of cancer less invasively, more quickly, and more accurately than existing methods.

“We are aiming to assist surgeons assess whether a cancer has spread or not, to be more precise with treatment to minimise side effects,” Prof Thierry says. “Cancer survival is getting better because we have more efficient treatment, and this means people are living much longer post-treatment. But if morbidity associated with the treatment is serious, as it often is currently, then that really impacts on the quality of life of the patient.”

With full clinical trials about to start at the Royal Adelaide Hospital for the Ferronova system, Prof Thierry believes the technology will allow treatments to be tailored to exact symptoms of specific patients, reducing both the toll cancer remediation takes on individuals and the burden it places on health resources.

“In a way this is a personalised treatment, finding the right solution for the particular case,” Prof Thierry says. “And we have consulted extensively with cancer surgeons about what they would like the system to deliver, and how it should be delivered, in order for them to do their job most efficiently.”

Professor Krasimir Vasilev is developing antibacterial coatings using nanospikes. Photo by Brenton Edwards.

Professor Krasimir Vasilev is developing antibacterial coatings using nanospikes. Photo by Brenton Edwards.

IMPROVING IMPLANT SAFETY

Since 1928, we’ve relied on drugs to destroy bacteria, generally by interfering with the development of cell walls (which is how penicillin works) or inhibiting protein production (which is how something like chloramphenicol treats conjunctivitis). However, with spiralling concern about the rise in antimicrobial resistance, there is an urgent need to find alternative means for eradicating bacteria, and nanotechnology is leading the way.

Bacteria generally range in size from 200nm to 10,000nm, and nanostructures at scales smaller than that can be used to physically destroy bacterial cells. Professor Krasimir Vasilev leads a UniSA team exploring techniques and applications for such antibacterial nanomaterials, and their research draws a degree of inspiration from mother nature.

“We are working with a leading Australian device manufacturer to bring to market the first ever orthopaedic devices with a nanoscale antibacterial surface to protect the device from harbouring infection,” Prof Vasilev says.

“The most unique part of the work is the use of clever nanotechnology, to create nanospikes on the surface that are 1000 times thinner than a human hair. Such tiny spikes have been used by nature for millions of years, to stop bacterial colonisations, such as on the wing of the dragonfly.”

Infections are the reason for more than half post-operative implant complications, and orthopaedic devices associated with infections can be very dangerous, suggesting the potential of this research is immense. “This is amazing technology that can improve the lives of millions of people around the world,” Prof Vasilev says.

Prof Vasilev’s team has also applied nanoscience to the development of a self-sterilising, painless drug delivery system. The technique consists of microneedle patches enhanced with silver nanoparticles to destroy bacteria as an inherent part of the injection process, helping prevent contamination and infection.

“We have demonstrated that our microneedle patch can kill a lot of medically relevant pathogens including Golden Staph and superbugs, but it does not harm mammalian cells and does not cause adverse inflammatory responses,” Prof Vasilev says.

Dr Aswathy Ravindran Girija is pioneering a novel aid to wound healing. Photo by Geena Ho.

Dr Aswathy Ravindran Girija is pioneering a novel aid to wound healing. Photo by Geena Ho.

HELPING WOUNDS HEAL

Colleagues of Prof Vasilev, including Professor Allison Cowin, Dr Aswathy Ravindran Girija, Dr Nirmal Goswami and Dr Sivakumar Balasubramania, are examining the potential of nanomaterials to treat infected wounds, an area in which the rise of antimicrobial resistance is a real concern.

“Wound healing itself is a complex process,” Dr Ravindran Girija says. “Infectious wounds are even more serious if the pathogen is multidrug-resistant, which significantly delays the healing process. In the past few years, nanotechnology has emerged as a promising platform to treat skin wounds.”

Dr Ravindran Girija and colleagues are exploring ways in which nanomaterials are beneficial not only as antibacterial agents, but also as means to boost the body’s ability to heal damaged tissue. They are using ultra-small gold nanoclusters, less than 3nm in size, combined with chitosan, a biocompatible antibacterial polymer widely used as a wound dressing material.

“We are developing novel wound-healing materials that are antimicrobial and also function as biocompatible ‘scaffolds’, which promote proliferation and migration of cells associated with wound regeneration,” Dr Ravindran Girija says.

By combining chitosan and gold as nanoaggregates, this technique has not only demonstrated novel antimicrobial and regeneration properties, it has also suggested a potential solution to existing concerns that gold nanoclusters may be toxic due to their incredibly small size.

“The gold-chitosan nanoaggregates assisted wounds to heal more rapidly without exhibiting any damaging effects in mammalian cells,” Dr Ravindran Girija says. “The synergistic action of gold and chitosan in the nanoaggregate enhances antibacterial activity against various bacterial strains compared to the individual components.”

The long-term goal is to integrate the nanomaterial into a wound dressing that would allow optimum healing of infectious wounds without the need for surgical intervention or antibiotic use.

“Nanotechnology offers a superior approach to accelerate the healing process of acute and chronic wounds,” Dr Ravindran Girija says. “By interfering with the different phases of healing using the one dressing, we hope to greatly simplify the treatment process.”

Dr Gary Owens and Dr Elliott Duncan are using nanomaterials to boost plant growth. Photo by Brenton Edwards

Dr Gary Owens and Dr Elliott Duncan are using nanomaterials to boost plant growth. Photo by Brenton Edwards

INCREASING FOOD PRODUCTION

There will be as many as two billion more people on the planet by 2050, and estimates suggest food production must increase by as much as 60 per cent to keep pace.

Future Industies Institute (FII) researchers, including Professor Enzo Lombi, Associate Professor Erica Donner, Dr Gary Owens and Dr Elliott Duncan are exploring one solution to the challenge – using nanomaterials to improve nutrient uptake in crops.

“Our initial engagement with nanoparticles was under-standing them as contaminants in soil and water,” Dr Owens says. “But exploring them in these environments, we came to understand they can also be beneficial.”

In parallel to assessing nano- material contamination risks – which remains an area of high priority – FII researchers are conducting a number of studies into the positive interactions between nanoparticles and plants.

“We recently completed a four-year project using zinc-oxide nanoparticles to treat soil zinc deficiency, a global issue causing low crop yield and malnutrition,” says Prof Enzo. “The results, using wheat, suggest there is scope to ‘tune’ nanomaterials to different plant species for optimum uptake.”

In a separate study, Dr Owens and Dr Duncan have seen similarly encouraging results with rice. While assessing toxicity of titanium and cerium nanoparticles in soils, the pair stumbled upon something unexpected. “Instead of appearing toxic, they actually improved the plant’s growth,” Dr Owens says.

While many details of the process remain unexplained, Dr Duncan says follow-up studies have been very positive. “These particles may provide some benefits for the plants, and, if we could harness those, this could be a big deal for the agriculture industry,” he says.

However, the area is being approached with appropriate caution. Ongoing research is considering both potential applications and any wider implications.

“In our zinc study, for instance, results suggest the nanomaterials dissolve quickly, with no specific toxicity effects in the soil,” Prof Lombi says.

“But if we’re going to consciously release these materials into the environment to benefit agriculture, we must be sure about any associated risks. As such, we’re not only studying the physical applications but also engaging with a range of stakeholders to understand the wider social dimensions.”

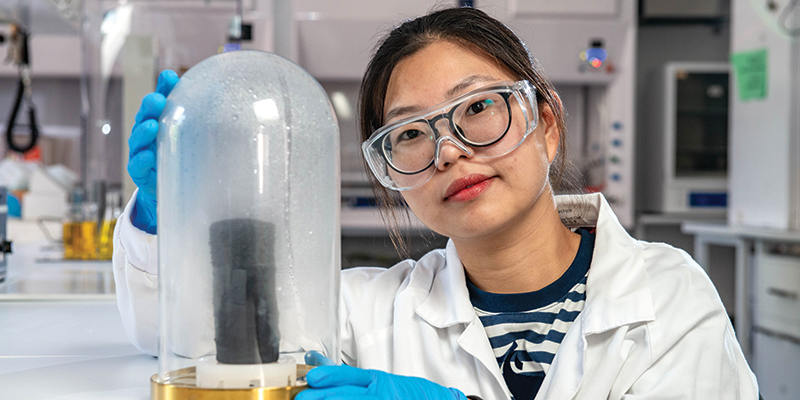

Dr Xuan Wu has developed a super-efficient photothermal desalination technique. Photo by Brenton Edwards.

Dr Xuan Wu has developed a super-efficient photothermal desalination technique. Photo by Brenton Edwards.

DRINKING OUR OCEANS

Seas are rising, rainfall is decreasing in many areas, and the UN estimates more than one in seven people will face water scarcity by 2025. Under the circumstances, it makes sense to perfect a cheap, reliable method for turning our swelling oceans into something we can drink.

While the concept of desalination has been around long enough for Aristotle to have written about it, the problem has always been efficiency. Even modern desal techniques, most commonly based on reverse-osmosis, require costly infrastructure and lots of energy to run.

Renewables are gradually bringing ongoing costs of largescale desal down, but nanotechnology is demonstrating the viability of passive purification techniques that essentially mimic the natural water cycle – the sun heats salt or brackish water to produce steam, which is collected and condensed into pure, potable aqua.

Dr Haolan Xu, a Foundation Fellow at the FII, and Dr Xuan Wu, are currently working in the water purification field, and have recently developed a new technique to deliver portable, passive solar-thermal desalination.

“We use a solid, absorbent reservoir, basically a cotton core, to hold seawater, and place it inside a photothermal sheet made from reduced graphene oxide and hydrogel coated cotton sheet,” Dr Wu says. “This system absorbs light and converts it into heat, thus evaporating the stored water.”

In the team’s device, no external seawater supply is required during solar-thermal desalination, and after a couple of days use, the photothermal reservoir can be easily recharged by immersing in seawater for five minutes.

While similar approaches have been tried in the past, all previous efforts required a bulk, liquid water reservoir, which causes problems with efficiency, and introduces the risk of spillage and contamination between the source and purified water.

By opting for the cotton reservoir, which can store 6.5 times its own weight in water, the team’s design overcomes these problems while also increasing the energy efficiency of the nanocarbon.

“The microstructure of the cotton towel provides the perfect site for the graphene oxide to attach, and also provides an enlarged surface area for evaporation,” Dr Wu says. “The light absorption and surface area of the nanocarbon are quite important, as they determine how efficient the light-to-heat conversion is for our use.

“We can currently produce about five litres to seven litres of clean water per square metre a day. We are aiming to get that to between 10 and 15 litres, and then this will be something we can bring to the market.”

FIND OUT MORE | Future Industries Institute